Product Information

Laser type

The SZ-1100 is the optimum model for research & development of high-definition 3D printed objects, and 3D printing of high-mix low-volume.

The laser spot diameter can be 15μm at minimum, and a telecentric fθ lens is adopted for the optical system, which enables stable microfabrication.

The variable laser output can respond to various materials, and applications can be selected according to purpose.

The SZ-2500 is a medium-size model that supports microfabrication to medium-size shaping.

The laser spot diameter is variable in a range of 50 - 300μm, which significantly improves drawing efficiency.

The 3D printing area is as wide as 250 × 250mm, where multiple small-size parts can be created simultaneously.

It is a versatile model that supports research & development through small-lot production.

DLP type

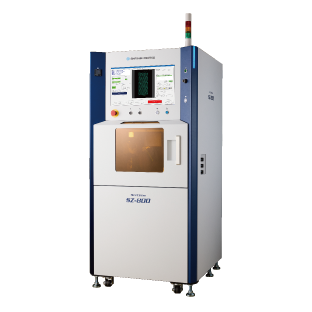

The SZ-800 is a standard model developed to realize easy operation, quick and precise modeling with DLP one-shot exposure for research and development use.

Wavelength is selectable from 365nm and 405nm to enhance flexibility of material choice.

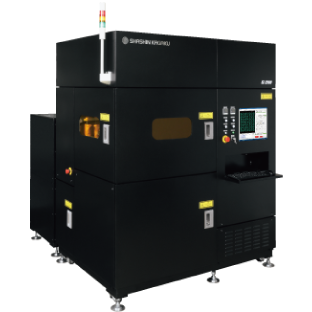

The SZ-6000 realizes high-speed exposure ten times faster in exposure time than our conventional model through adoption of a newly developed DLP multiscan method.

Furthermore, high-definition drawing quality is achieved as the drawing spot size is 21.6μm and the control pitch is 0.9μm.

The 3D printing area is as large as 660 × 600 × H300mm, enabling high-volume simultaneous 3D printing in batches.

This solves mass production problems related to conventional 3D printers.

The SZ-6000 is a mass-production-oriented model that can maintain conventional drawing quality, enabling high-speed large-area 3D printing.

Equipped with functions specific to a mass-production machine

- Equipped with an external large-capacity automatic slurry replenishment unit, which enables long-time continuous operation without running out of materials.

- Equipped with surveillance cameras that monitor defects during 3D printing.

- Equipped with the functions of blade cleaning and surplus slurry recovery, which enable effective use of surplus materials in 3D printing.

- Equipped with a conveying table that smoothly carries out a green body on the stage to the cleaning process after large-area 3D printing.

List of specifications

|

|

|

|

|

|---|---|---|---|---|

| High-definition model SZ-1100 |

Productivity/3D printing area expanded model SZ-2500 |

Standard model SZ-800 |

Mass-production model SZ-6000 |

|

| 3D printing area | 100 × 100 × H50mm | 250 × 250 × H250mm | 80 x 55 x H50mm | 600 × 600 × H300mm (70kg) |

| Layer pitch | 10~200µm | 50~200µm | 10~200µm | 10~200µm |

| Spot diameter | Φ15~80µm | Φ50~300µm | - | - |

| 3D Printing Resolution | - | - | Dot 35μm | Dot 21.6µm/Drawing pitch 0.9µm |

| Output power | 250mW | 1000mW | - | - |

| Equipment size | 1300 × 1750 × H1650mm | 1600 × 1850 × H1950mm | 800 x 900 x H1700mm | 1720 × 2950 × H1870mm |

| Power supply | Single-phase 100V AC 1.0KVA | Single-phase 100V AC 1.5KVA | Single phase 200V AC 2A | Single-phase 200V AC 30A |

Slurry dispersion

The SZ series, which aims at high-definition 3D printing, requires slurry making as microscopic particles are more highly filled. Therefore, optimum slurrying of various materials is realized by using our revolution-rotation planetary centrifugal mixer “Kakuhunter” that can adjust the ratio between revolution and rotation.

- Revolution-rotation planetary centrifugal mixer

“Kakuhunter” -

- Revolution-rotation planetary centrifugal mixer

- Revolution-to-rotation ratio separate control system

-

- Creation of optimized slurry

-